For over 60 years, we have been specialising in painting in Casirate d'Adda

ContactFor over 60 years, we have specialised in liquid and powder painting of various types of metal and plastic with metallic finishes, textures, soft gum-touch, RAL, NCS, and Pantone colours. We offer conductive shielding paints and antistatic coatings.

We perform liquid and powder coatings with any type of finish, with the possibility of applying mixed cycles (powder + liquid) on ferrous materials. We also carry out puttying and smoothing, deburring, and screen printing on any surface and material.

Additional services: Galvanising and Black Cathodic Electrodeposition.

Pick-ups and deliveries with our vehicles.

Industry experience:

EXHIBITORS, VENDING MACHINES, GENERAL ELECTRONICS, LIGHT METALWORK, AUDIO AND VIDEO APPLIANCES, OUTDOOR AND INDOOR LIGHTING, ACCESSORIES FOR FIREPLACES AND STOVES, GARDEN FURNITURE, URBAN FURNITURE, INTERIOR FURNITURE, MEDICAL EQUIPMENT.

Verniciatura Ci-Elle… We give colour to your ideas...

Characteristics of painting booths

All our painting booths are state-of-the-art.

They are pressurised and water veil booths to provide the best in terms of finish and compliance with environmental regulations.

They are large double-station booths that allow us to paint iron and aluminium structural parts well beyond 5 metres in length.

Every phase of our work is carried out safely, respecting all regulations to protect our staff and the environment. Verniciatura CI-ELLE is a well-known company in the province of Bergamo, as well as in Milan and Brescia, for its seriousness and professionalism.

Colour and technology at your service

eriousness and professionalism are the foundation of CI-ELLE's business. Specialised in liquid and powder painting of various types of plastic and metal, the workshop uses various colour charts, including RAL, Pantone, NCS, FEDERAL USA, and MARSHAL colours specific for each type of application requiring particular colours and shades.

Each painting operation is carried out with state-of-the-art equipment and technologies to optimise costs, raise quality standards, and reduce delivery times. Furthermore, the company performs puttying and smoothing, deburring, and screen printing on any surface and material.

Depending on the object to be painted, the company employs a different technique of industrial painting, liquid or powder, through mixed cycles, with the possibility of having any type of finish. Verniciatura CI-ELLE performs painting on plastics, wood, and ferrous materials with metallic finishes.

Experience and flexibility at the service of customers

Verniciatura CI-ELLE has been active in the third-party industrial painting sector for over 60 years, using only state-of-the-art machinery. The company in Casirate d'Adda boasts extensive experience and different painting techniques, both powder and liquid.

The Bergamo-based company has two adjacent production units located in Casirate d'Adda, near Bergamo.

Painting departments

The painting departments operate through a well-defined company policy aimed at creating exclusively high-quality products, with full attention and respect for current regulations.

Over the years, our company has become an important reference in the painting sector, particularly for the many customers who have chosen to collaborate with us, from the DESIGN world to the realms of LIGHTING and ELECTRONICS.

Our sincere thanks to all of them.

The added value of VERNICIATURA CI-ELLE lies in the ability to handle significant quantities of items, made from different materials, with very rapid turnaround times and excellent finishes.

Furthermore, to complement our production range, we have introduced innovative products and processes over the years, including the use of:

- Antistatic conductive paints

- Highly insulating Teflon paints

- Conductive shielding paints based on nickel, copper, and pure silver

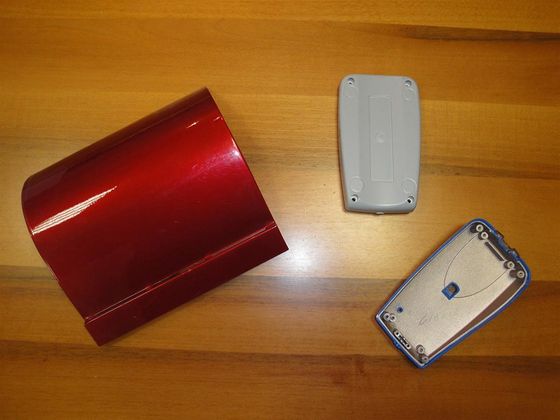

PLASTIC COATINGS

At our company, every type of plastic and polyurethane is painted.

Each type of plastic is primed differently based on the raw material it consists of, to ensure maximum adhesion to the final paint film.

In the painting cycle of plastic materials, conducted in pressurised booths, there are stages of drying, curing, sanding, and puttying that contribute to the final result of the painted object.

The plastic coating process involves, as the first step, washing and degreasing the plastic material so that the paint can adhere perfectly.

HIGH-TEMPERATURE SILICONE PAINTING

RESISTANCE TO 600°C HEAT

High-temperature silicone painting is carried out in specific stations applying silicone cycles resistant to high temperatures.

Liquid paints from the best European manufacturers are applied, after pretreatment, on metallic artefacts, and then dried at over 200°C for an hour in ovens.

This allows the painted and applied film to withstand continuous temperatures exceeding 600°C.